In a groundbreaking move, Germany-based polymer manufacturer Covestro has entered into a strategic 5-year collaboration agreement with San Francisco-based quantum computing software developer QC Ware. Together, they aim to develop cutting-edge quantum computing algorithms that have the potential to revolutionize Covestro’s manufacturing processes and materials.

At the core of this partnership lies the belief that quantum computing could be the game-changer that computational chemists have been waiting for. Covestro’s Head of Group Innovation, Torsten Heinemann, expressed his conviction, stating, “We are fully convinced that the technology of quantum computing will give computational chemists a decisive boost in the future.”

The fields of chemical manufacturing and materials science are intricately linked, where minuscule changes at the molecular level can yield significant macroscopic impacts. Computational chemists are tasked with dissecting microscopic structures, delving into the intricacies of electron movements within substances, and deciphering the quantum world of chemistry. These efforts are crucial for optimizing processes and materials, leading to improved efficiency and cost savings in industries such as renewable energy and chemical manufacturing.

However, the sheer complexity of quantum-level computations has posed significant challenges for traditional supercomputers. As a result, simplifications and approximations have been necessary to make these computations feasible. While this approach accelerates calculations, it often comes at the cost of precision and quality.

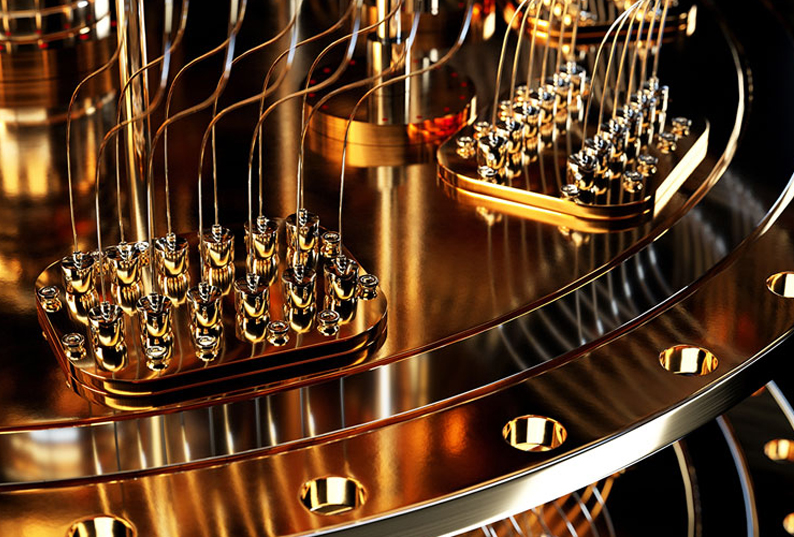

Quantum computing offers a glimmer of hope by leveraging the principles of quantum mechanics to perform calculations that were previously deemed unattainable. Rob Parrish, QC Ware’s Head of Chemistry Simulations, explains that quantum chemistry aligns naturally with quantum computing. The fundamental concept revolves around replicating one quantum system within another, eliminating the need for approximations and delivering results that mirror quantum systems accurately.

Covestro and QC Ware embarked on this collaborative journey over the past year, aiming to create a proof-of-concept for simulating reactions relevant to industrial applications. Their collaborative work has yielded two significant papers. The first introduces novel techniques for simulating chemistry with fewer quantum computing resources, while the second pioneers a method for calculating energy gradients essential for simulating critical chemical processes.

Although current quantum hardware has limitations that prevent it from running large-scale simulations required by the partners, the collaboration focuses on developing software and algorithms, primed and ready for the day when quantum computing hardware matures. Their goal is to deploy these quantum computing solutions on the best available hardware within the next five years.

In the short term, Covestro aims to apply these innovations to its chemical manufacturing processes, particularly those dependent on catalytic reactions. Quantum hardware currently under development, expected to be accessible within a few years, will facilitate simulations for these processes. By enhancing this aspect of chemistry, Covestro anticipates more efficient processes with reduced waste production, translating to increased output, higher product quality, and lower energy consumption.

Additionally, Covestro and QC Ware plan to explore the circularity of manufacturing. Global legislation is increasingly oriented toward enabling the recycling of polymers and materials into their original components rather than disposing of them in landfills or incinerating them. Quantum computing is expected to play a pivotal role in realizing this vision.

In the long term, both companies foresee quantum computing driving more sophisticated simulations that open up new possibilities for product manufacturing. Covestro envisions breakthroughs in renewable energy, with quantum computing facilitating the design of superior solar panels and battery systems. QC Ware anticipates not only developing quantum software and algorithms for materials manufacturers but also extending its reach to applications like drug discovery.

Matt Johnson, Co-Founder and CEO of QC Ware, emphasizes the mutual benefits of this partnership. Covestro gains access to quantum computing expertise, enabling internal product development and market offerings. The collaboration illustrates the power of global networks in driving research and development efforts, bringing together the right expertise to achieve a common purpose.

In conclusion, Covestro’s partnership with QC Ware signifies a quantum leap in the world of chemical manufacturing. By harnessing the potential of quantum computing, they are poised to unlock new horizons in materials science and manufacturing processes. As quantum hardware continues to evolve, the collaborative effort between Covestro and QC Ware is a testament to the transformative impact that quantum computing can have on the chemical industry and beyond.